Believe it or not, Kanye West saw this day coming. Back in 2015, the hip-hop and fashion legend admitted he was afraid that 3D printing would ruin the textile industry. “There will come a time where it’s like, people will be making their shoes at home,” he said. Well, Mr. West, that day may have finally arrived, as a German mechatronics engineer has just proven that it is possible to 3D print custom, comfortable high-heels entirely on a desktop 3D printer.

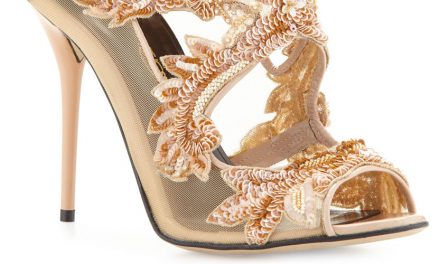

Though we have seen quite a few stunning 3D printed high heel shoes, the majority either come fromhigh-end designers, or else they are so ‘fashion-forward,’ they wouldn’t make sense for most of us to wear in real life. Shoes, and especially high-heels, must take into account balance, fit, shape, flexibility, multiple materials, and a myriad of other factors to be considered wearable, making them quite difficult for your average desktop 3D printer. There’s a reason we’ll go to great lengths to find the perfect pump.

But now, Markus, a mechatronics engineer and 3D printing hobbyist, has proven that homemade, 3D printed high heels are possible—and has made his wife a very lucky woman in the process.

Markus, who told 3Ders.org that he has no previous experience whatsoever in shoemaking, began by creating a 3D model of his wife’s most comfortable old pair of high heel shoes in order to capture the exact size, shape, and curve that she preferred. In order to do this, he first took apart the original shoes and snapped 52 individual photographs. He included several markings, which helped Autodesk 123D Catch capture a full and accurate 3D model.

The 3D high heel shoe model was then refined in Meshmaker and imported to SoldWorks, where Markus got to work on modifying the style and design of the heel itself. “I played a bit around and tried to make a design which looks ‘3D printed,’” he told us. He thus chose an architectural, hollowed-out heel design to show off the capabilities of layer-by-layer 3D printing technology.

Once ready, Markus used ABS filament and his Rostock MAX 3D printer, a desktop machine from SeeMeCNC available for $999, to 3D print a 1:2 scale model, and finally, the finished version. When asked, Markus said that he chose the Rostock MAX because of its “high speed, large build volume, and good price,” adding that he had included a few personal upgrades, including his own flying extruder modand a Prometheus V2 hotend.

“It took approximately 8 hours and 64m of ABS filament per shoe on my Rostock MAX,” he said. The final dimensions of the 3D printed high heels are 80 x 123 x 193 mm each. He then finished them off by sewing on a colorful straps, chosen by his wife, to keep her feet comfortably in place.

Of course, what it all comes down to is the fit and feel. As someone who’s suffered from long nights in bad shoes, as soon as I saw the first images, my first question was, “can she actually wear them?”

Markus’ answer was a resounding “Yes!” “She walked around a lot, no problems so far. I had a good feeling the ABS would be strong enough. [And] the fit is very good because I scanned her most comfortable heels.” To further improve the design and the 3D printed shoes’ wearability, Markus plans to add a leather insole, and potentially even rubber soles to increase the grip.

For the moment, however, Kanye West can rest easy. Markus has no plans to begin 3D printing custom-made shoes on a mass scale, and therefore won’t be ‘disrupting’ the textile industry any time soon. He said that although the 3D design and even 3D printing process was relatively smooth, sewing on the adjustable straps was extremely time-consuming. He also has no plans to release the STL files to the public. “I discussed about that, but my wife wants to be the only one in the world.”

Markus studied Mechatronics in Dresden, and has always been passionate about robots—in fact, he even 3D printed roughly 1800g of parts for a robotics project with ex-TURAG members, which won theEurobot German Championship and placed 4th internationally. He has since taken up desktop 3D printing has a hobby, mainly 3D printing useful, household items such as a spice rack, mobile phone holder, and even an Inmoov Hand for a friend.

With Valentine’s Day right around the corner, a custom pair of 3D printed shoes would certainly make a great gift—and now you know all that’s needed is an old comfy pair to 3D scan, a desktop 3D printer, and a bit of creativity.